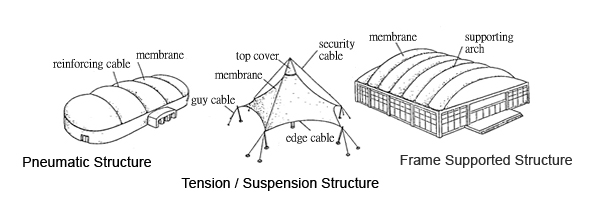

Typical Membrane Structures |

Membrane will be formed in the final 3D shape by inducing tension forces in the membrane. The membrane will obtain rigidity, only when being in tension, against external forces and serve as structural element according to the design criteria.

|

|

| The membrane structure is generally categorized in three types, Pneumatic Structure, Tension Structure and Frame Supported Structure |

| ◎ Frame supported membrane structure |

| The membrane is supported by the structural steel or glulam structure. The membrane will take external forces and transfer the loads to the supporting structure along the perimeter interface. As supporting structure will eventually take loads, frame supported membrane structure is the most stable and commonly used system in typhoon and heavy snow areas such as Japan and Taiwan. The roof shape is fairly simple and suitable for enclosed buildings. Generally estimated steel weight ranges about 40to100 kg/m2 |

| ◎Tension Membrane Structure |

| Tension structure consists of membrane material, tension cables and axial steel members and is stabilized with the balance of such components. Tension structure is giving most attractive design shape expressing the characteristics of membrane material. In 1990s, modified tension membrane structures with the combination of cable net, compression/tension rings and axial struts have been developed and applied to large roof projects. As this system heavily relies on the balance of large tension and compression forces in cables and struts, interface connection as well as foundation should be taking large axial forces. Generally the unit weight of steel for tension structures is lighter than frame supported structures ranging 5 to 20kg/㎡ |

| ◎ Pneumatic membrane structure |

| The pneumatic membrane structure is the air inflated system. The membrane roof will be pressurized by blower and inflated by air to the final designed shape. The internal and external pressure difference is about 20mmAq (20kg/m2). Pneumatic membrane structure is normally applicable for covering a large space without allowing supports inside the space. Reinforcing the membrane roof with structural cables, this system can be applied for large span domes over 100m diameter. Most enclosed large span membrane domes built in 1980s are pneumatic structures. The major disadvantage of the system is that the blowers must be running 24 hours a day in order to maintain the internal pressure which is essential to stabilize the structure. Therefore, other structural system with lower maintenance requirements has been recently preferred by clients for large scale domes permanently used. |